Packaging your vision. Building your legacy.

India’s trusted name in rigid plastic packaging with three decades of experience, from design to delivery, with sustainability at the core, we make your product stand out.

High-Quality Packaging

Solutions for Your Products

With over 34 years of domain leadership in rigid plastics, Wellmac Plastics Private Limited delivers packaging that protects your product and strengthens your brand.

We specialise in blow moulding HDPE bottles and injection moulding HDPE closures and PPCP buckets and lids, delivering durable and reliable packaging solutions for pails and containers. In a nutshell, driving innovation with a strong focus on eco-friendly and sustainable practices.

Our Core Strengths

Decades of Proven Excellence

Performance at the Pinnacle

Certified for Global Standards

Strength in Infrastructure

Commitment to a Greener Future

Trusted Partnerships & Global Reach

Service Categories

Extrusion Blow Moulding

Autodeflash technology.

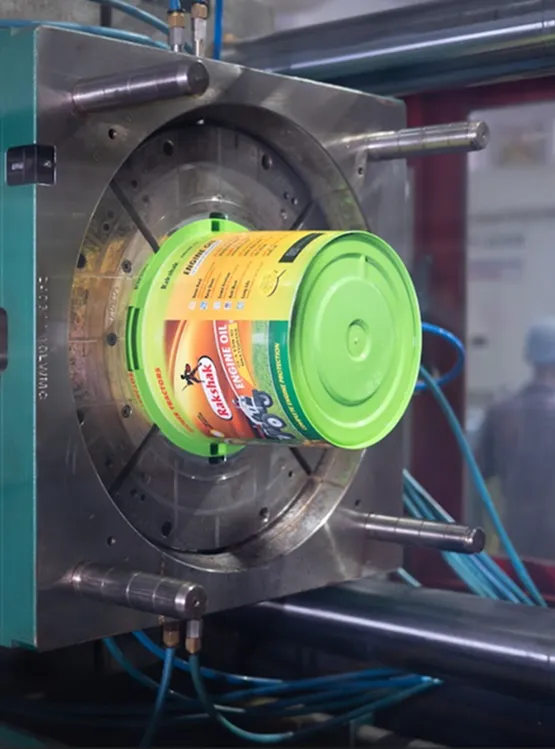

Injection Moulding

Caps, lids and buckets with advanced IML facilities.

Precision Labelling

& Quality Assurance

Auto-labelling with advanced vision

systems ensures accurate and

planned execution.

Partner with us for precision-engineered packaging that powers your brand.

Future - Ready

Packaging Solutions

End-to-end packaging expertise powered by advanced injection and blow moulding machines. Our facilities are equipped with state-of-the-art technology, including fully automated deflash systems with mono and multilayer closed-loop facilities.

By integrating high-tech automation with sustainable practices, we maximise efficiency, reduce material waste, and enhance productivity, delivering packaging solutions that are not only innovative but also environmentally responsible.

Manufacturing Infrastructure

With over 2,00,000 sq. ft. of advanced manufacturing space, our facilities are built for precision, scale and innovation. Each plant is equipped with cutting-edge machines to meet diverse product requirements.

Our spacious storage facilities enable safe and organised material handling, supported by high-speed production lines that ensure consistent quality at scale, and efficient dispatch systems designed to meet customer timelines with precision.

Facility Footprint & Capabilities

- Unit 1 Multilayer extrusion auto deflash blow moulding

- Unit 2 Double colour caps injection moulding & spout covers

- Unit 3 Advanced injection moulding & post moulding decoration

- Unit 4 Conventional monolayer blow moulding

350+

No. of Employees

25+

Blow Moulding Machines

27+

Injection Moulding Machines

US $22.5 million +

Turnover in F.Y. 2024-25

9500 Metric Tonnes

(capability of churning 10-12K metric tonne per year)

Polymer Converted in F.Y. 2024-25

20+

No. of Happy Customers

Good well-managed setup. A combination of various technologies. Total end-to-end in-house setup for supplies of lube containers. Wish you all the best for future expansions & growth.

Mr. Dinesh Kolambkar

It’s always great to meet up with strong business partners like Wellmac! Keep up the good work, Safe practices & innovations. I wish for a long-term relationship between Shell and Wellmac.

Mr. Shemal Mehta

Great team to deliver the product to the customers with a proactive approach. Keep it up.

Mr. Sanjeev Wangoo

Good Operation by automation!

Dr. Toshiaki Kusaba

Excellent Layout. Very impressive unit. Bright working environment- All the best!

Mr. Ravi Chawla

Very well laid out plant. Happy to see you are continuously innovating and bringing in newer technologies. Keep up the good work.